|

Printed from: www.oicinc.com on

|

|

| http://www.oicinc.com/drinkingfromthefirehose.html |

|

|

|

| Sea Technology

Article: Drinking from the Fire-Hose |

| By: Tom Reed, president of Oceanic Imaging

Consultants, Inc.,

INTRODUCTION

The acquisition of seafloor mapping data has matured remarkably

in the past decade. This article reviews some of these advances,

with particular attention to how some new technologies have effectively

dealt with "data-overload" made possible by sensors with

greater resolution and bandwidth.

Seafloor mapping - while admittedly potentially a complex, detail-intensive

task involving numerous electronic sensors, telemetry systems and

logging/display devices - can be, and often is best thought of,

as making pictures of the bottom of the sea. Pictures, as we all

know, contain a lot of information. A typical 35mm color slide,

at 9000 scan lines per inch and approximately a 4x3 aspect ratio,

contains over 2.5 Giga-bits of information. Clearly, mapping the

seafloor can be highly data-intensive, resulting in data overload

on both operators and logging devices. "The Matrix" notwithstanding,

people do not deal gracefully with scrolling alpha-numeric byte-streams.

Scrolling pictorial representations (waterfalls, graphic recorders,

etc.) are the usual solution, but often with compression in both

physical resolution, and data dynamic range. With recording mimicking

display, loss of resolution, or reduction in survey coverage and

pace, was considered inevitable. These mandatory losses are now

a thing of the past. Sustainable, 24-7-365 reliable logging and

real-time processing of seabed mapping data at rates in excess of

10 mega-bytes per second is available in commercial, off the shelf

PC-based packages today.

HISTORICAL PERSPECTIVE

At a first glance, seabed mapping systems can be categorized into

two families: acoustic systems, such as echo-sounders, sidescans,

multi-beams and swath-interferrometric devices, and non-acoustic

devices, such as traditional cameras and videos, electronic still

cameras (ESC's) and laser linescan systems (LLS's). We recognize

that profiling systems such as single and multi-channel seismics,

magnetometers and gravimeters are equally important mapping tools,

but for the moment restrict our analysis to systems providing imaging

in the traditional planimetric format.

A typical two-channel analog sidescan system actually provides

a large amount of information. Fortunately, roll-paper records are

quite efficient at gathering this, albeit somewhat difficult to

carry around in significant quantities. When taken to the digital

domain, a quantitative notion of the data available to us becomes

apparent. Assume a reasonable digitization rate of 24 KHz, yielding

a constant slant-range resolution of 3 centimeters. Assume 16-bits

sample resolution to encompass the likely range of raw backscatter

variations in amplitude. This implies a data rate from a simple

two-channel sidescan of approximately 100 Kbytes per second, or

360 megabytes per hour. This will fill a Zip-disk in 15 minutes,

and a 1 GB Optical platter in under 3 hours. To people planning

a 30 day cruise, this begins to look expensive. In steps downsampling.

Perception is everything, they say. A high-quality roll-paper

recorder can display 4096 samples across a scan, and you don't need

to hire a programmer to show your boss the data. For the typical

sidescan mentioned above, this would allow you to show full resolution

data for any swath of 50 meters range or less. At any range greater

than that, you would have to throw away some of the data. At 100

meter range, you would have to throw away half the data, for example.

Furthermore, the human eye can only distinguish between 16 and 32

shades of grey. This translates to retaining at best one third of

the original dynamic range. If you take this same data to an XGA

computer monitor, you are limited to only 1024 samples across a

line, and a depth resolution of 8-bits. Let's assume you may have

2 screens, so now, in theory, you would need to log only 1024 samples

per side, 8-bits per sample to make maximum use of your digital

display system. If you operate at 100 meters range or greater, and

only log what you display, you have irretrievably discarded over

75% of your data. No amount of post-acquisition signal processing

magic can bring this lost data back. Furthermore, any operator-induced

changes to gains, contrast stretches, etc. are likely to be permanent.

Logging raw data at full resolution and full dynamic range obviates

these problems. It just requires media space, and through-put bandwidth.

NEW DEVELOPMENTS

In 1997, the United States Naval Oceanographic Office (NAVOCEANO)

embarked upon a fleet modernization program for its T-AGS 51, T-AGS

60 and T-AGS 45 class oceanographic survey vessels and accompanying

Hydrographic Survey Launches (HSL's). Mission requirements included

high-resolution sea floor mapping and object location/identification

in littoral areas of the world, typically under adverse environmental

conditions. Specific requirements included simultaneous acquisition,

display and logging of dual-frequency sidescan sonar data, single

and multibeam bathymetry, and beam amplitude and backscatter. Per

the specification, the maximum anticipated data rate would be up

to 1 Gigabyte per hour, which the sonar data acquisition workstation

would be required to log to both tape and hard-drive. Anecdotally,

this prompted the requirement for at best a 9 GB hard drive, as

it was mentioned that "...no government worker was ever required

to work more than an 8 hour day...".

|

Figure 1. NAVOCEANO Hydrographic survey launch (34' LOA).

|

Oceanic Imaging Consultants (OIC) was selected to provide

GeoDAS as the Sonar Data Acquisition and Processing workstation for

the T-AGS ships and HSL's, interfacing to the Datasonics SIS1502 Dual-frequency

sidescan, as well as the Simrad EM3000 for multibeam bathymetry and

backscatter.

The rack-mount GeoDAS workstation, as shown below, was delivered with

dual 1280x1024 monitors, dual 18-GB hard-drives, and dual 20 GB Exabyte

Mammoth tape drives. A quad-port Ethernet card allows simultaneous

receipt of both the broadcast Simrad multibeam bathymetry and TSS-PosMV

navigation and motion sensor data, as well as re-broadcast of processed

OIC records of merged sidescan and bathymetry to client workstations,

either on the launch, or at a remote location, via Ethernet Radio

Link. The latter technique allows observers back on the host T-AGS

ship or land to view raw or processed data from the HSLs as the data

are being acquired, offering both immediacy of analysis, and easy

remote trouble-shooting of any data quality issues which might arise. |

Figure 2. GeoDAS equipment rack aboard NAVOCEANO ship, with

dual 1280x1024 monitors, rack-mount keyboard, CPU, Sonar MUX and printer,

plus integrated winch controls, USBL tracking unit & deck cameras.

|

The sidescan on the HSL's is a Datasonics SIS1501/2

dual-frequency system. The 1501 model indicates CW technology, while

the 1502 indicates that the sonar can operate in both CW and Chirp

mode. GeoDAS interfaces to and controls the SIS1501/2 through the

through the Datasonics multiplexor and proprietary.dll, which allows

full control of sonar range, wet-gains, pulse type, length and power,

as also provide both sensor telemetry and a continuous 192 Kbytes

per second data feed. GeoDAS logs all this data raw, without any filtering

or downsampling, and then applies user-specified processing to allow

realtime data display in a variety of views (profile, waterfall, mosaic).

The multibeam on the HSL's is the Simrad EM3000s, a 300 KHz sounder

which provides 127 beams over a swath of upto 200 meters or four times

water-depth, in waters from 0.5 to 150 meters deep. The system outputs

both raw and corrected bathymetrye datagrams over a 10 Mb/sec UDP

link. It can also broadcast both beam amplitude (average backscatter

per beam) and the raw time-series backscatter data at full resolution

(3 cm). GeoDAS catches all these datagrams and logs them in parallel

with the SIS1501 sidescan data, and offers the user options for both

processing and display selection. By default, the console will present

a waterfall showing platform and sidescan attitude, course, etc.,

along with synchronized color-contoured bathymetry, and either low

or high-frequency sidescan. The user may modify views and processing

on the fly without interrupting data logging, to optimize onboard

analysis such as target detection and survey status. |

Figure 3. GeoDAS user interface, showing color-contour bathymetry

in parallel with sidescan (100 or 500 KHz). |

| The combined data streams from the sidescan and multibeam

comes to just under 1 GB per hour, which GeoDAS logs continually to

dual Exabyte 8900 tape drives, and optionally prints to a rack-mounted

roll-paper recorder. The operators may also elect to create realtime

mosaics of both the sidescan and bathymetry data, in a variety of

projections, at user-definable scale and orientation. The geo-coded

mosaics can be export to an on-board GIS package, and merged with

existing data for quick-look mission products. |

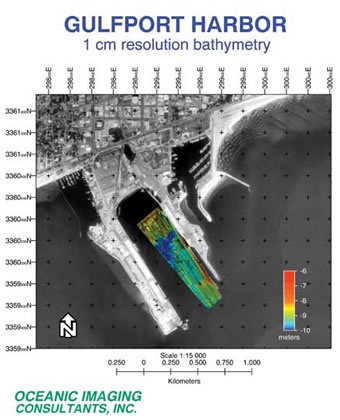

Figure 4. "Quick-look" mission product created from

HSL bathymetry and sidescan, mosaicked at 1 centimeter resolution

and merged with available air-photo data for the surrounding region.

|

DOUBLE OR NOTHING...

In the fall of 2000, OIC began work on an interface to the Raytheon

LS-4096 Laser Linescan system. The LS-4096 provides continuous 14-bit

imagery from a scanning laser mounted on an underwater vehicle.

Resolution is configurable from 512 to 4096 samples per scan line,

at scan rates up to 4000 RPM. At maximum resolution, the LS-4096

delivers 2.2 Mbytes per second, at approximately 267 scan lines

per second. This data rate doubled that which had been required

of GeoDAS in the past, and exceeds conventional sonar imaging requirements

by at least a factor of 100, if not more. The original top-side

processor allowed saving of user-selected "snapshots",

but any continuous data logging could only be accommodated on video

tape, which could not take advantage of the full imaging resolution

potential of this system. Any geo-coding of data required manual

"cut-and-paste"operations post acquisition.

GeoDAS-LLS provides a complete control, processing and display

interface to the laser linescan system, treating the data stream

as a single-channel sidescan (albeit, a VERY FAST sidescan). This

includes full resolution raw data logging, as well as realtime and

post-acquisition processing, targeting and geo-coding. The laser

data can even be merged with co-registered sidescan data, to provide

an ultra-high resolution "gap-filler" directly beneath

the track of the sonar. Co-registration of sidescan and laser imagery

provides significant improvements for search and recovery, bottom

characterization and mine-hunting operations, with the laser data

offering the potential of on-the-fly target identification, augmenting

the sonar's extended abilities for target detection. |

Figure 5. GeoDAS-LLS, showing data from the Raytheon LS-4096.

|

NOT JUST ANOTHER PRETTY PICTURE...

This spring, OIC completed it's modifications to GeoDAS to support

Electronic Still Camera imaging. The completed interface retains the

"look-and-feel" of the orginal GeoDAS user interface, while

allowing continuous acquistion, processing and display of single or

dual camera imagery, at data rates up to 10 MB per second. The interface

supports multiple modes of display, including scrolling, binocular

and single image view, to accommodate images up to 1280 by 1280 pixels

on a side, at 16-bits dynamic range. A dual camera configuration at

one Hertz frame rate in continuous operation mode will fill a 60 GB

8-mm tape in just over 2 hours. Dual tape-drives allow automatic roll-over,

for uninterrupted logging (provided you brought A LOT of tapes...).

Retaining the basic GeoDAS format while accommodating data records

easily 1000 times more than your average sidescan record proved challenging,

but the result provides the same processing, targeting, logging and

QA/QC interface as available for scan-line based systems, minimizing

operator re-training, and maximizing product reliability. |

Figure 6. GeoDAS-ESC, in the dual-camera configuration.

|

DATA INTEGRATION

While the above examples demonstrate available solutions for the

mechanics of multi-sensor, high-rate data acquisition, there remains

the issue of operator overload, and interpretation. Simply put,

someone has to look at all this. If we can now simultaneously acquire

swath acoustic data, providing a half-kilometer swath of acoustic

imagery and bathymetry, and optical data, providing sub-centimeter

scale imagery over a patch which might barely cover the nadir footprint

of the sonar, how are we to co-register and compare the two modalities?

ROVer's Eye, a real-time terrain visualization package developed

by OIC under DARPA funding, provides one option. ROVer integrates

a hi-speed 3-D rendering package with GeoDAS's realtime-processing

and target analysis package, to provide an interactive immersive

experience, wherein underwater vehicle operators can work not only

with existing models, but see new data from on-board sensors evolve

into the current model in realtime. ROVer accommodates simultaneous

inputs from sidescan, bathymetry and navigation systems, while accessing

a database of existing data, targets and as-built structure models.

Operators see new data evolve in a model before them, just as headlights

reveal the road ahead to night-time drivers. "Road-signs"

in ROVer reveal not gratuitous advertising (nor Burma Shave ditties)

but full resolution images of proximal targets, which "pop-up"

as the vehicle passes by. The combination of synoptic swath data

with detail-rich target imagery in a fully geo-coded environment

provides a whole new level of data interpretation experience. |

Figure 7. ROVer's Eye view of the bottom of Honolulu Harbor, with

TargetView mode on, providing automatic notification of proximity

of previously marked targets. |

SUMMARY

Seafloor imaging is a data-intensive process. Down-sampling strategies

compromise both image resolution and quantitative information potential.

GeoDAS, an off-the-shelf solution for acoustic and non-acoustic seabed

data acquisition and processing, can provide a uniform interface to

sonar, laser and camera-based imaging systems, handling raw data rates

up to 10 MB per second with no down-sampling losses, while retaining

realtime interactivity. Examples are provided from working installations. |

Dr. Thomas B. Reed IV is founder and president of Oceanic

Imaging Consultants, Inc. of Honolulu, HI. He received his undergraduate

education from Harvard University in 1982, where he majored in Economic

Geology, and completed his graduate work in Marine Geology and Geophysics

at Hawaii Institute of Geophysics, in 1987. |

|